Joint Folding

To produce this kind of folding some researches and tests have been made, in order to obtain the mix of the nitrile rubber with feature of resistance to the oil and to the fire.

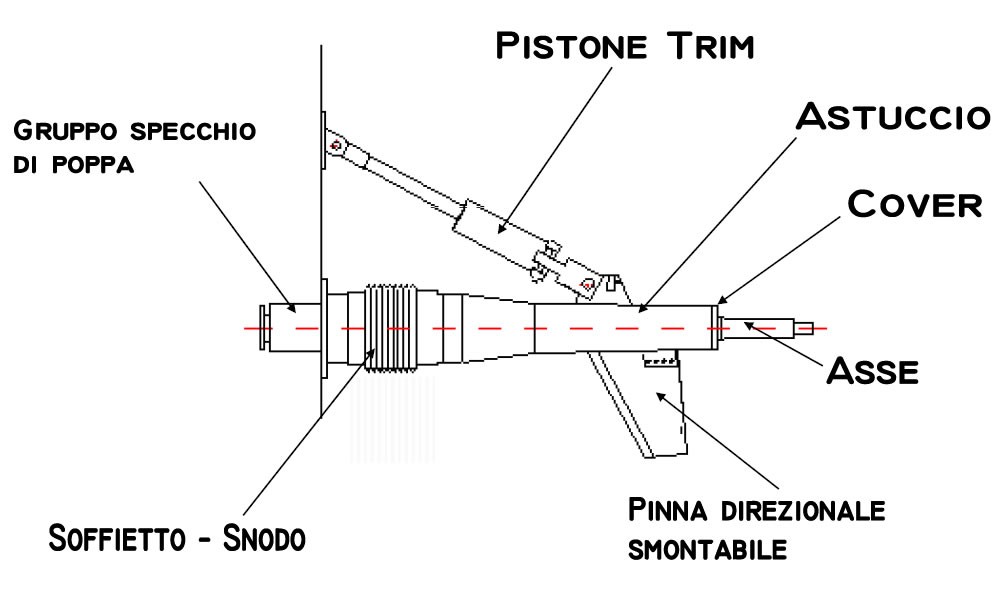

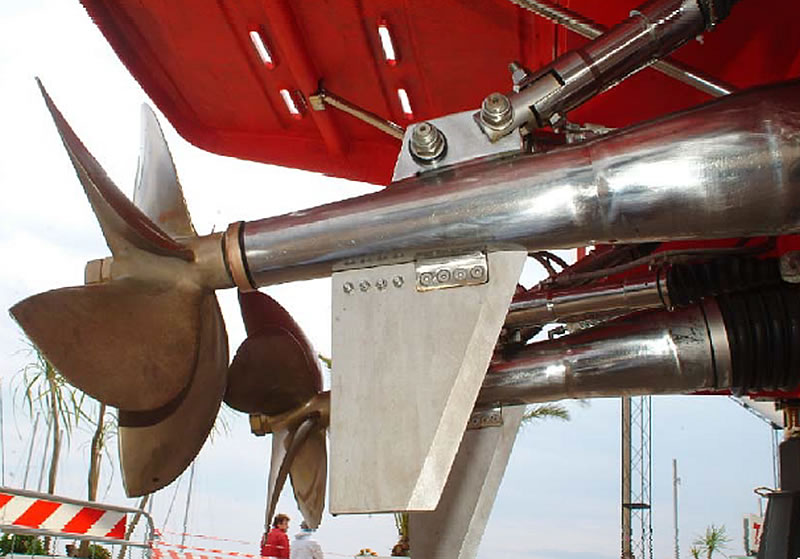

Surface Drive TS Components

Components of the propulsion Surface Drive Top System

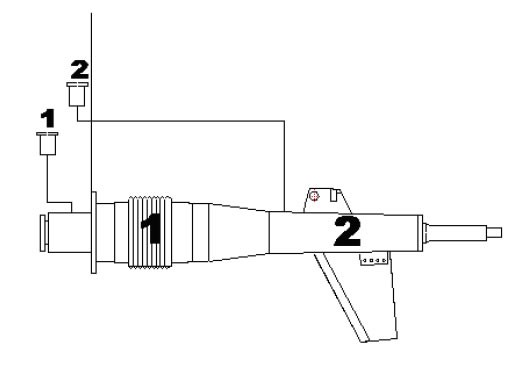

Lubrication surface propellers drive

Inside the engine room there are two level tanks which allow to visualize the levels and to control the infiltrations.

The filling of the first room has to be done by a pump equipped with a drain cap.

The second room has to be filled always by a pump with motor oil SAE 15/40.

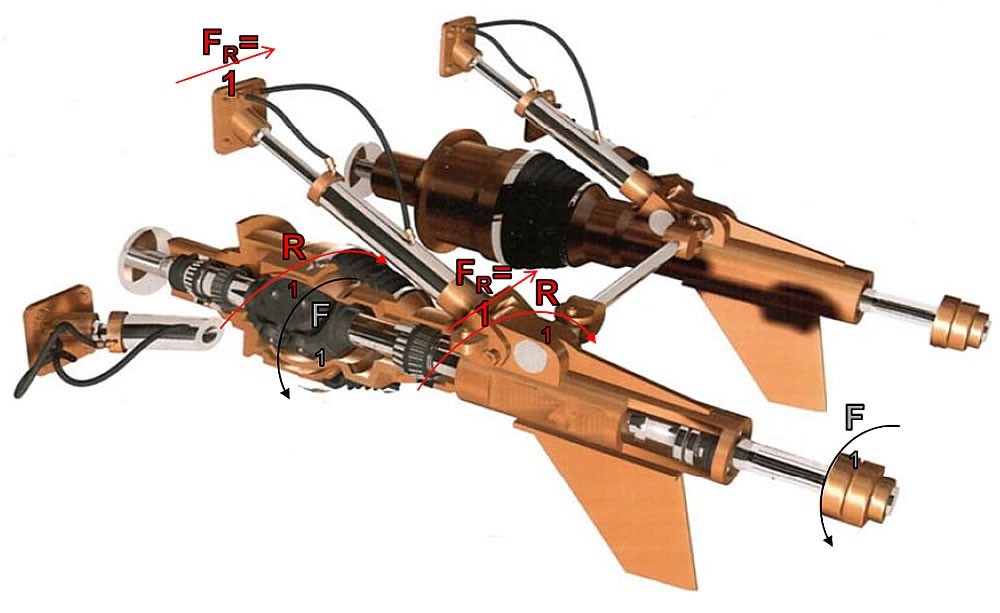

Main Top System Features

Driving Top System is easy and safe, because also at high speeds there is the total lack of vibrations and unexpected reactions to the rudder, thanks to the exclusive power-assisted steering gear system.

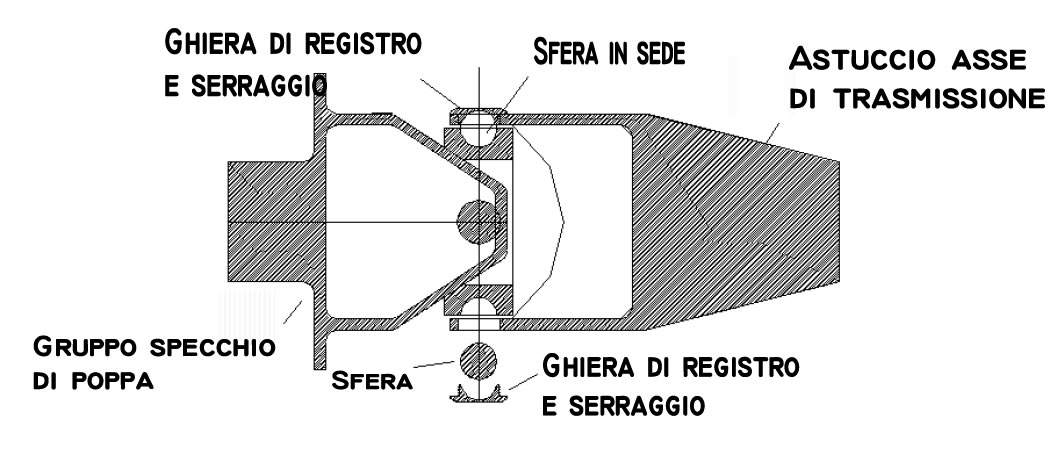

Top System Joint

Drive with trim and surface propellers, branded thanks to the patented Top System Surface drive joint.

Hydraulic systems

Trim equipment: the control is given from the pilot bridge by a joystick, which activates an electro-valve and an electro-hydraulic pump which, through an operating pressure of about 100 BAR, puts in motion the cylinder.

Competing Propulsion Systems Surface Drives

Currently, the supercavitating propellers propulsion systems made on the market, which use joint systems called “ball joint”, present structural problems originated from failures of mechanical components.

Directional Fin

Top System has been the first drive to adopt the directional fin, which can be dismantled. This solution allows faster maintenance interventions, possibility to change the fin dimensions, opportunity to change it in case of impact.

Top System Hydraulic Cylinders

The cylinders are suitable to connect on the same structure the indicating wires and the sacrificial anodes. The hydraulic fitting is stainless 316.